HI-TEN STEEL FRAME AND ALLOY FRAME

Fuji-ta Group has the largest modern frame production base in the world, and owns more than 60 bicycle frame production lines, including over 30 hi-ten steel frame lines and over 30 alloy, carbon fiber and new-material frame lines. It can manufacture hi-ten steel frames, 6069/6061 alloy frames, carbon fiber frames, magnesium alloy frames and other new-material frames. All products have passed South Korean KS quality system certification, Japan SG certification, US CPSC, European Union EN standards and so on, reaching the world top level. The hi-ten steel frame manufacturing center of Fuji-ta Group has the globally advanced production equipment, such as more than 100 sets of frame welding robots imported from Swedish ABB corporation, auto-cutting and wrapping machine, multi-functional down-tube punching machine, bottom bracket automatic processing machine, CNC iron machine, hydraulic tube forming machine, argon arc welding machine, automatic phosphate coating machine, T4/T6 heat treatment, calibration stand, CNC bottom bracket reaming & tapping machine, etc. While promoting the production process of our company, the advanced processing equipment also improves the work efficiency, reduces the costs of raw materials and manpower, as well as provides clients with the first-class products and services through technical means.

AUTO-CUTTING AND WRAPPING MACHINE

The auto-cutting and wrapping machine is cutting the pipes, enabling the size of each pipe to be accurate.

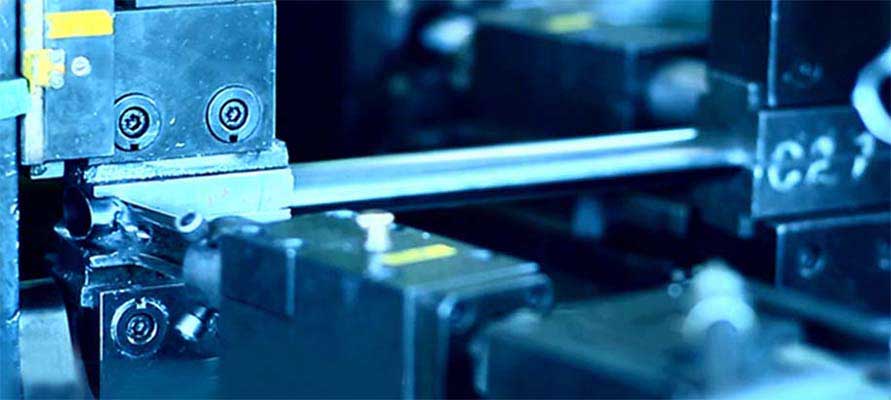

MULTI-FUNCTIONAL DOWN-TUBE PUNCHING MACHINE

The multi-functional down-tube punching machine is cutting the pipes, ensuring the welding pipes to fit more tightly.

Welding robot

More than 100 sets of bicycle frame welding robots are imported from Swiss ABB Corporation, with high precision, good performance, maximized production & processing efficiency and greatest safety.

BOTTOM BRACKET AUTOMATIC PROCESSING MACHINE

CNC MACHINE

Bottom bracket automatic processing machine and CNC machine have overcome the deficiency that the traditional punching hinge milling cannot realize the curve processing and three-dimensional processing, so as to guarantee the product quality.

CNC DIE PROCESSING MACHINE

Fuji-ta Group achieves the development and production of dies independently, and pays attention to every detail. In the picture, the die grinder is processing the frame molds.

HYDRAULIC TUBE FORMING MACHINE

Hydraulic tube forming machine can produce frames of any shapes according to the appearance design requirements, which realize the diversified frame shapes. The hydraulic die forming machine is molding the pipes.

ARGON ARC WELDING MACHINE

The argon arc welding is operated by professional senior personnel, ensuring the beautiful flower patterns.

AUTOMATIC PHOSPHATE COATING MACHINE

The automatic phosphate coating machine standardizes all soaking time, ensures the uniform frame cleanliness and coating effects, and thus guarantees the coating adhesive force. It far surpasses the industrial level.

CALIBRATION STAND

The calibration stand enables the precise concentricity. In the picture, the professionals are calibrating the frame.

T4/T6 FURNACE HEAT TREATMENT

The most advanced T4/T6 furnace heat treatment process in China adopts the Taiwanese aluminum heat treatment furnace and the advanced thermal radiation method, makes each frame part get uniform heat and stable constant temperature, and thus provides more protection over the strength of each frame.