LITHIUM-ION ELECTRIC BICYCLES

Professional R & D and production of lithium-ion electric bicycles

Tianjin Fushida group E-biek company was founded in 2009, is a professional engaged in lithium-ion battery electric bicycle R & D, production and sales of scientific and technological innovation oriented enterprises.

The company inherited the Group advanced bicycle manufacturing experience, into today’s most advanced lithium-ion battery technology, FOC vector frequency control technology, built-in motor system, torque sensor, and have cycleurope (DBS, Bianchi), specialized, Halfords, Pegasus cooperation and o2feel, the world’s best brand, and success as the output of high-quality products.

The company has always been adhering to the quality is the cornerstone of enterprise survival and development, is the lifeline of the enterprise, has invested a lot of money to build electrical parts laboratory. The inspection and testing methods for lithium ion batteries have reached the first-class level in the industry. The company’s production of each lithium tram battery to go through rigorous testing of the electrical laboratory, to ensure that each group of factory lithium battery 100 percent qualified. To ensure the consistency of product reliability, we focused on the product characteristics and requirements of the body every moment the locking screws were prescribed torque, and require all bolts must have locking means, the most important thing is that we have a special test in the workshop on the lane, Lane in different positions of the marked sections need to test the project after all, the product line will try to ensure that the product is absolutely the resistance.

ENVIRONMENT SIMULATION EXPERIMENT

Extreme temperature environment simulation experiment

- imulation of the motor in a very low or very high ambient temperature of the fatigue performance of the experiment, the impact of large load experiment.

- Simulation of the cycle life of the battery at very low or very high ambient temperature, start-up performance, discharge performance, etc.

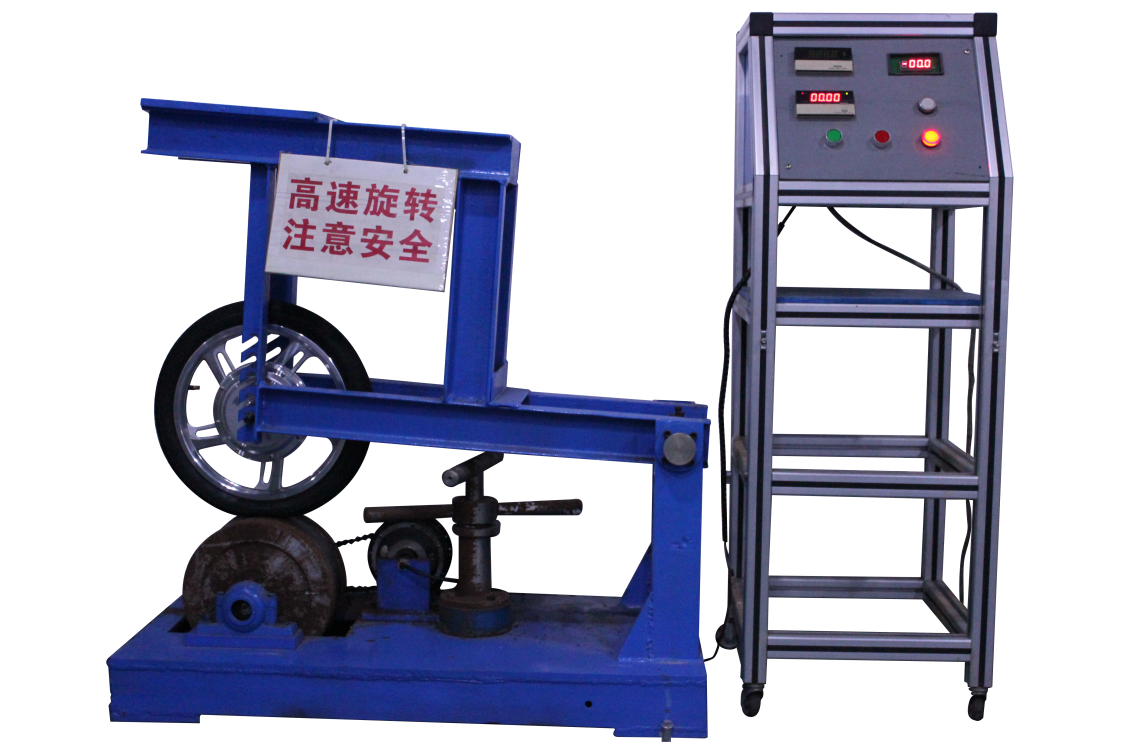

MOTOR AND CONTROL SYSTEM

The fatigue performance of the motor and control system

- Simulation of the motor load at room temperature bumps, start and stop and other aging experiments.

- Fatigue performance test of analog controller under normal temperature and high current load.

TEST OF POWER LOCK

Electrical and mechanical performance test of power lock

Mechanical performance and electrical performance of analog power lock with small load.

Motor performance test

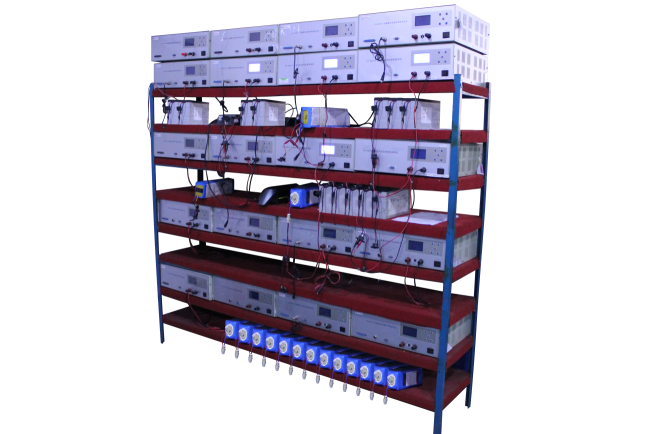

LIFE OF LITHIUM ION BATTERY

Test experiment of cycle life of lithium ion battery

- Test experiment of cycle life of lithium ion battery

BATTERY PERFORMANCE TESTING

Battery performance testing

- Battery performance testing

- Battery discharge performance and capacity

CHARGER MAXIMUM LOAD AGING TEST

Charger maximum load aging test

- Charger maximum load aging test

- Charger large current aging test

Insist on technological innovation and management innovation, with large-scale production capacity, advanced detection ability for strong backing, to build the core competitiveness of enterprises, and strive in the near future to build up a lithium ion battery electric OEM, the world’s largest platform.