CARBON FIBER BIKE FRAME AND NEW MATERIALS

Fuji-ta Group’s carbon fiber bike frames and spare parts are sold well to Japan, South Korea, Taiwan, Europe, and many countries and regions.Fuji-ta Group is an OEM for lots of internationally renowned brands, and it has maintained stable customer relations with more than 10 foreign clients.

Aimed at the new materials, new technologies, new processes of modern bicycle, the company takes the initiative to develop bicycles made of carbon fiber, carbon magnesium composites and carbon aluminum composites in the domestic market. New materials, new technologies and new processes have fully covered the current cutting-edge technological innovation and technology development direction of the global bicycle industry, and reached the world advanced level.

CARBON BIKE FRAME

FRAME MANUFACTUR

FRAME MANUFACTUR

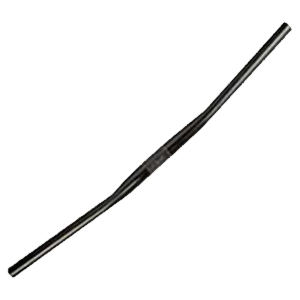

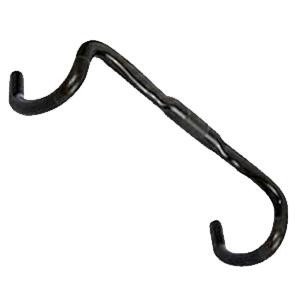

Fuji-ta Group’s carbon fiber products mainly consist of lightweight carbon fiber bicycle frames, handlebars, front forks and seat tubes. The weight of carbon fiber road bicycle can reach 8.5 kg; the weight of carbon fiber mountain bicycle can reach 11.5 kg. Carbon fiber bicycle frames, handlebars, front forks and seat tubes have high strength, with better performance indicators than alloy products. Also, they have passed European EN quality standards.

FRAME MANUFACTUR

Fuji-ta Group’s carbon fiber products mainly consist of lightweight carbon fiber bicycle frames, handlebars, front forks and seat tubes. The weight of carbon fiber road bicycle can reach 8.5 kg; the weight of carbon fiber mountain bicycle can reach 11.5 kg. Carbon fiber bicycle frames, handlebars, front forks and seat tubes have high strength, with better performance indicators than alloy products. Also, they have passed European EN quality standards.

FRAME MANUFACTUR

Fuji-ta Group’s carbon fiber products mainly consist of lightweight carbon fiber bicycle frames, handlebars, front forks and seat tubes. The weight of carbon fiber road bicycle can reach 8.5 kg; the weight of carbon fiber mountain bicycle can reach 11.5 kg. Carbon fiber bicycle frames, handlebars, front forks and seat tubes have high strength, with better performance indicators than alloy products. Also, they have passed European EN quality standards.

FRAME MANUFACTUR

Fuji-ta Group’s carbon fiber products mainly consist of lightweight carbon fiber bicycle frames, handlebars, front forks and seat tubes. The weight of carbon fiber road bicycle can reach 8.5 kg; the weight of carbon fiber mountain bicycle can reach 11.5 kg. Carbon fiber bicycle frames, handlebars, front forks and seat tubes have high strength, with better performance indicators than alloy products. Also, they have passed European EN quality standards.

NEW MATERIALS NEW TECHNOLOGIES AND NEW PROCESSES

Fuji-ta has successively made an investment of 160 million Yuan to build high-end carbon fiber bicycle frame and spare parts factories, purchased more than 350 pieces of equipment, attracted a large number of excellent technicians, and established a carbon fiber plant with an annual output of 150,000 sets of carbon fiber frames, and 2 million spare parts with the highest technical contents and largest production scale in Northern China. The improvement in overall bicycle level aims to comprehensively enhance the assembly and processing qualities of middle and high-end products and strengthen the product technicality.

STRENGTH AND RIGIDITY TEST

During the quality control evaluation process, namely, before the mass production, all frames and spare parts will be rigorously tested. Fuji-ta Group owns testing equipment which conforms to different global quality standards. The fatigue test and dynamic test of frames and spare parts will be used for evaluating the long-term durability, in order to guarantee the product safety and feasibility before production.

PRECISION CUTTING CARBON FIBER MATERIALS

Carbon cloth cutting is the key to achieving high-quality laminate. Fuji-ta has paid careful attention to handling all original carbon cloths. The company precisely controls the laminate angle and thickness of each carbon fiber, and guarantees the consistency of products. It is also an important part for building lighter and stabler product structure with less carbon fiber.

SEPARATING PROCESS

A carbon frame has more than 200 pieces of carbon cloths with various sizes, and the cut carbon cloths will be separated and sorted one by one.

INNER MOLDING TECHNOLOGY - PRELIMINARY MOLDING

Fuji-ta has extremely high requirements over the preliminary molding of carbon fiber products. When bearing huge loads, the frame joint can be kept intact through excellent shape. The key to this step is to pre-stress the raw materials, which adopts purely manual operation.

INNER MOLDING TECHNOLOGY - MOLDING

In the molding process, you need to solidify the carbon fiber preliminary products under the standard pressure and temperature, and each laminate will be subject to the pressing force, which will increase the structural integrity and further optimize the carbon fibers.