TITANIUM BIKE FRAME

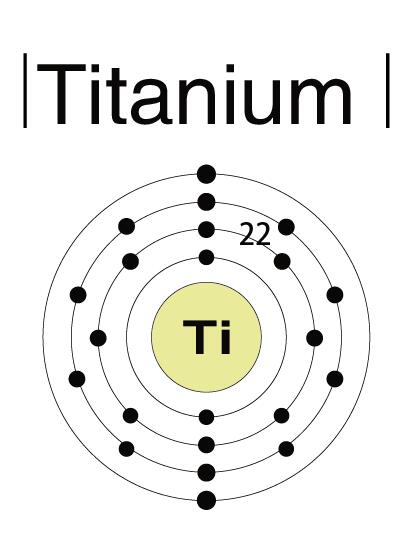

Titanium bike frame is a silver-gray transition metal which ranks 22nd in the periodic table. It can apply in high strength, light weight and anti-corrosion alloy.

Ti-alloy is high performance material which apply to aerospace technology filed widely, Low density, High specific strength, Excellent resistance of fatigue and corrosion, excellent comprehensive performance.

WELDING TECHNOLOGY

Titanium bike frame.We use TIG (argon arc welding) to produce bicycle frames. It’s important for bicycle frame strength to guarantee welding quality, so we emphasize both technology and workers’ technical requirement. We ensure the quality with a series of strict procedures, for example we pay close attention to fuse the solder wire and tubing edge effectively, to meet demand of high-strength with moderate weld width and perfect fish scale. That is why our titanium bicycle frames are guaranteed for the lifetime of our customers. It will accompany with you for your life.

PROCESSING TECHNIC

Adopting special equipments and jigs, we seriously control the dimensional tolerance to ensure the quality in every process, meanwhile, to ensure to give perfect expression of production design and processing mode, which is the key to guarantee quality.

Aiming at the customers’ demand for lighter bicycle frames, we research and develop double-butted tubing for bicycle frame, which guarantee bicycle frame’s strength as well as lower weight.

According to customer’s individuation requirement, we design and machine the tubing into different shapes, such as ellipse, water drop, taper and diamond. We research and develop hydrofortned tubing to meet the requirement of increasing stiffness and strength of bicycle frames, to highlight the texture of bicycle frame, to fit modern fads of titanium bike design.

We make our products to be excellent not only in model but also in quality with precise casting technique, CNC machining, engraving techniques and polishing treatment by hands. Especially it can compare with handwork,which has become collection of numerous cyclists.

EXPERIENCE

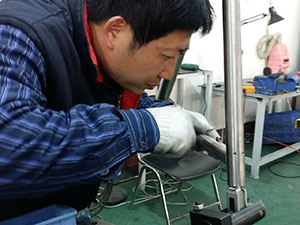

Exquisite mechanic with over 20 years experience is polishing the frame, treat each frame as his kid.

Sandblasting craftsman is manual matting for the frame,make every line and point accurate.

Polishing of Ti-alloy frame is totally made by hand.

Polishing of Ti-alloy frame is totally made by hand.

Excellent welding technology- Beautiful scaly figure.