TESTING LABORATORY

Fuji-ta Group’s Testing Laboratory owns more than 300 sets of advanced testing equipment, and invests over 50 million Yuan successively. In 2014, Fuji-ta Group’s Testing Laboratory obtained Laboratory Accreditation Certificate issued by China National Accreditation Service for Conformity evaluation (CNAS), and was accredited by International Laboratory Accreditation Cooperation – ILAC-MRA. Currently, Fuji-ta Group is the only enterprise that has obtained the accreditation in the Chinese bicycle industry.

INTERNATIONAL LABORATORY ACCREDITATION COOPERATION

ILAC (International Laboratory Accreditation Cooperation) is an international organization for accreditation bodies operating in accordance with ISO/IEC 17011 and involved in the accreditation of conformity evaluation bodies. Its testing laboratory runs in accordance with ISO / IEC 17025 standards, and the testing results can obtain mutual recognition among 72 laboratory accreditation bodies in China and other 58 economic entities. Besides, the accreditation bodies are established in many economic entities, and ILAC mutual recognition Agreement was signed by 55 accreditation bodies from 45 countries and regions, including Australia, Austria, Belgium, Brazil, Canada, China, Cuba, Czech Republic, Denmark, Egypt, Finland, France, Germany, Greece, Hong Kong China, India, Indonesia, Ireland, Israel, Italy, Japan, Korea, Malaysia, Mexico, Netherlands, New Zealand, Norway, the Philippines, Poland, Portugal, Romania, Singapore, Slovakia, Slovenia, South Africa, Spain, Sweden, Switzerland, Chinese Taipei, Thailand, Turkey, the United Kingdom, the United States, and Vietnam. By establishing the peer evaluation system, ILAC forms the international multilateral mutual-recognition mechanism, and promotes the application of accredited laboratory results through multilateral agreements to reduce the technical barriers. Fuji-ta’s global laboratory mutual recognition avoids unnecessary repeated evaluations, and lays a foundation for achieving the goal of “one test and global recognition”.

ADVANCED TESTING EQUIPMENT

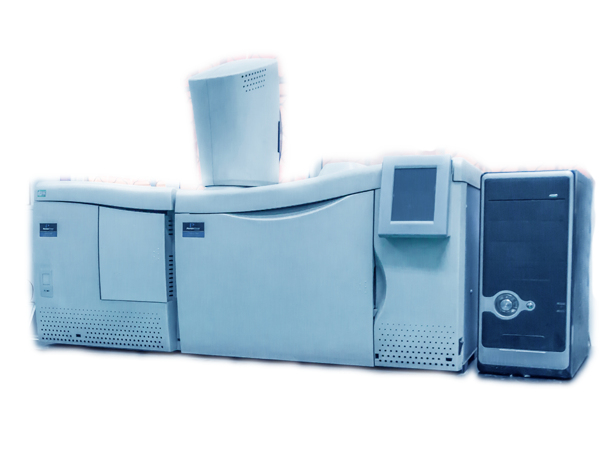

Fuji-ta Group’s Testing Laboratory owns the world-class testing equipment, including PerkinElmer (PE) Clarus500GC- Gas Chromatography/Mass Spectrometry (GC/MS), precision linear LABSPARK 1000 spark spectrometer manufactured by Nake Analytical Instruments Co., Ltd., as well as salt fog spraying test machine, EDX fluorescence spectrometer, five frame fatigue testing machine, microwave extraction instrument and other advanced testing equipment, all of which represent the highest quality testing standards in the bicycle industry.

Gas Chromatography/Mass Spectrometry (GC/MS)

Fuji-ta Group’s Testing Laboratory adopts GC/MS manufactured by US PerkinElmer, in order to analyze the material components of bicycle products. The manufacturer PerkinElmer is a global analytical instrument manufacturer. The purchase price is more than 1 million Yuan, and it is the best testing device in the Chinese bicycle industry. Its working principle lies in analyzing the sampling components of materials, in order to test the conformity of each component. GC/MS provides strong supports for the qualitative and quantitative analysis of complex compound during the judicial identification process, guaranteeing the reliability and safety of Fuji-ta products.

Disc Braking Road Tester

Fuji-ta Group’s Testing Laboratory adopts the microcomputer bicycle disc braking road tester manufactured by Chun Yen Testing Machine Co., Ltd., in order to test the intensity of bicycle braking system. The purchase price is more than 600,000 Yuan. It can simulate the braking safety in dry and wet environments, and carry out the load and obstacle tests in the dynamic strength test, ensuring Fuji-ta products to cope with various situations in the real environment and guaranteeing the product safety.

Frame Head Tube and Seat Tube Fatigue Life Tester

Fuji-ta Group’s Testing Laboratory adopts EN Microcomputer Frame Head Tube and Seat Tube Fatigue Life Tester manufactured by Chun Yen Testing Machine Co., Ltd., in order to test the vertical and horizontal fatigue life of bicycle frame head tube and seat tube. The purchase price is more than 600,000 Yuan. It conforms to EN ISO standard and all the following standards. Its working principle lies in carrying out the repeated pushing and pulling tests from the vertical and horizontal angle under the fixed pushing and pulling forces & frequency. If the products are not damaged in the pushing and pulling process at a fixed frequency, they are acceptable products. The equipment testing is conducted in strict accordance with the standards, in order to ensure the service life and safety of products.

DRUM ABRASION TESTER

FRAME FORK DYNAMIC FATIGUE TESTING MACHINE

MORE SPECIALIZED TESTING EQUIPMENT

SPECTROMETER TESTING MACHINE

Other Tests, SummaryGAS CHROMATOGRAPH-MASS SPECTROMETER;GC/MS

Other Tests, SummaryULTRAVIOLET CLIMATE RESISTANCE AGING TEST BOX

Other Tests, SummarySALT WATER SPRAY TEST CHAMBER

Other Tests, SummaryDIRECT-READING SPECTROMETER

Other Tests, SummaryROCKWELL HARDNESS APPARATUS

Other Tests, SummaryTHE ELECTRIC BOARD BURST TESTER

Other Tests, SummaryCARDBOARD COMPRESSIVE TESTER

Other Tests, SummaryWEAR-RESISTANT TEST FOR B.B PARTS

Parts Detection, SummaryBRAKE’S LIFE OF ROAD TEST MACHINE

Parts Detection, SummaryCRANK ASSEMBLY FATIGUE TESTING MACHINE

Parts Detection, SummaryWEAR-RESISTANT TEST FOR FRONT AND REAR HUB

Parts Detection, SummaryTHE OPERATING PROCEDURES IN TESTING OF DYNAMIC LASTINGNESS WITH PEDAL

Parts Detection, SummaryADVANACED MICROCOMPUTER MATERIAL TESTING MACHINE

Parts Detection, SummaryBRAKE LEVER FATIGUE MACHINE OPERATING RULES

Parts Detection, SummaryTHE OPERATING PROCEDURES IN STATIC LOAD TESTING MACHINE OF AXIAL DIRECTION PRECISION

Parts Detection, SummaryTHE HANDLEBAR FATIGUE TESTING MACHINE

Parts Detection, SummarySADDLE FATIGUE TESTING MACHINE

Parts Detection, SummaryFRAME TRANSVERSE FATIGUE TESTING MACHINE

Frame Detection, SummaryFRAME PEDAL FORCE FATIGUE TESTING MACHINE

Frame DetectionTHE FORK FRAME VIBRATION TEST PROCEDURES

Frame DetectionTHE OPERATING PROCEDURES IN TESTING OF THE FRAME AND FORK DROP DOWN

Frame DetectionTHE FORK FRAME ASSEMBLY DROP TEST PROCEDURES

Frame DetectionWEIGHTED BB DROP TEST FOR DUAL SUSPENSION

Frame DetectionTHE FRAME LONGITUDINAL FATIGUE TESTING MACHINE

Frame DetectionFORK FATIGUE TESTING MACHINE

Frame DetectionTHE OPERATING PROCEDURES IN STATIC LOAD TESTING OF DRIVING SYSTEM

Frame DetectionMICROCOMPUTER BRAKE DISC OF BICYCLE BRAKING FORCE ROAD SERVICE LIFE TESTING MACHINE

Frame DetectionSEAT POST FATIGUE TESTING MACHINE

Frame DetectionEN MICROCOMPUTER FRAME HEAD SOCKET PIPE

Frame Detection